Before buying your first container of RTA kitchen cabinets, there’s things you should know. In this article we’ll look at the basics so you don’t make a beginner’s mistakes that could cost you. Here is the information for you to consider as you buy your first container of RTA kitchen cabinets.

1. How Many Cabinets Should You Start With?

If you have never bought a container before, your temptation will be to “give it a try” with only one container. The issue here could be warehouse space.

However, if finances are the underlying motivation behind this statement, I’d suggest that you wait until you can purchase two containers. Then you can purchase a third within a month or two after receiving your initial two.

Here is part of my thinking.

If you are going for a broad inventory of SKUs, then with one container you will have limited stock for each SKU. As part of a broad inventory, you’d probably need either 30″ and 36″ wall cabinets or 36″ and 42″ or 30″ and 42″, depending on your market. Once you factor in pantry cabinets and the corresponding complementary heights of wall cabinets like 12″ – 27″ high and some 24″ deep for over refrigerators, your inventory can be spread pretty thin with a single container.

Now if you know that you can serve your market with limited heights of wall cabinets – then go for it.

Also, take a look at 3-drawer bases. Within the standard sizes of 12″ – 36″ wide drawer bases, you can consume a lot of cabinet count in that range.

One container isn’t enough unless you have a backup supply somewhere, and you are okay dollar cost averaging your lower cost container with your higher cost stick from an existing US supplier.

Further, even with a backup supply, when color matching or matching species that are not the factory standards, you are likely to need two containers minimum.

2. What is the Cost of Importing RTA Kitchen Cabinets by Container?

A container can hold 600 – 700 cabinets. Thus, the typical cost of a container is $65,000 – $70,000, plus foreign manufacturer-to-domestic-warehouse shipping.

Of course, your mix of cabinets, vanities, tall cabinets, moldings, panels, etc. will impact the total cost of the cabinets in your container.

Factory=to-warehouse shipping costs fluctuate seasonally as the result of global events and things like container shortages, to name a few cost drivers.

Shipping costs for a container under normal circumstances can spike from $8,000 in January to $12,000 in months where Christmas inventory is building in the US market.

3. When is Payment Due?

A down payment of at least 30% is due with the order. Then the balance comes due as cabinets get close to port.

4. Should You Use a Broker or Import on Your Own?

A broker is a company that:

- Adds a percentage to the cost from the factory as their fee

- Provides payment to the factory

- Can provide other help as they deal with the factory often and know how they operate

- Makes things easier with the customs process

- Has the bond and works with customs and your freight company to clear your shipment

However, when considering a broker, your normal due diligence process for evaluating individuals and the associated pitfalls needs to be in play. This a bigger question than I’m going to cover here.

If you decide to try importing without hiring a broker, you need to get a customs bond. Important information regarding the customs bond can be found here. As you read through this info, you’ll get a better understanding of the scope of what you’ll need to do if not using a broker.

5. How to Assemble Your Inventory List

Assembling your inventory list is not an easy thing to do, but you purchase history is the best place to start.

Consider:

- Do you need 33″ and 36″ susan cabinets

- How about 3- and 4-drawer bases

- What height walls and talls do you nned

- How many widths of pantry cabinets do you need

You’ll get your best answers from your existing customer base and purchase history. Or use your current suppliers’ list of SKUs to start thinking through what you’ll need to order.

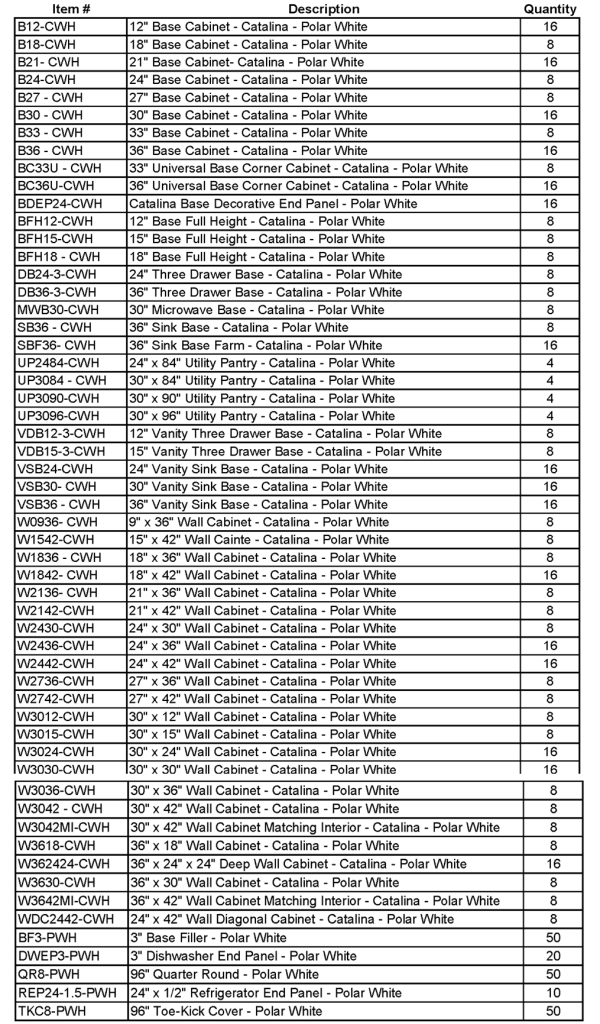

Here’s a sample pick list, just to give you an idea. Plus, we can supply you with other lists to help get you started.

6. When to Buy Your Refill Container

When considering finances and warehouse space, keep in mind that you have 3 to 4 months wait for your next container. Plan accordingly to have enough money and space for your next container(s).

7. How Are RTA Cabinets Packed in the Shipping Container?

Working with a good factory will enable you to max out how your container load of RTA cabinets is packed.

8. What Equipment is Needed to Unload the Shipping Container of RTA Kitchen Cabinets?

Basically, you’ll need to get labor, as most shipping companies will not leave a container for you to unload in a day or two. Figure 3 hours with 4 – 5 people. Also, this number is for unloading only. Racking your container happens at different times.

Depending on your freight carrier, there is a time limit for unloading your container. As soon as you open the doors to the container, the clock starts. Normally, you have three hours to unload before additional fees are assessed. Expect around $100 per hour for any time you keep the driver beyond three hours.

You’ll need pallets to keep your unloading rolling. Also, both a pallet jack and/or forklift is beneficial to help move the cabinets. One to remove the loaded pallet from the truck and the second to move into position to keep unloading the next pallet.

For extra convenience, a gravity expandable conveyor system speeds things up and helps reach the back of the 40 ft container.

9. What’s the First Step to Unloading Your Container?

Before any unloading can happen, you need to cut the bolt on the container, then open the doors. It’s not possible to back the container into your dock and then open the doors.

10. How Will You Unload Your Shipping Container of RTA Kitchen Cabinets if You Don’t Have a Dock?

The pictures and examples we provide next assume you have a dock. As you’ll see, the cartons getting unloaded are not RTA kitchen cabinets. However, you’ll get an idea of how to plan and what you need to think through to unload your container.

If you don’t have a dock, start making space by unloading from the container to a pallet on the floor of the warehouse. Once you have created space inside the container, you can load your pallet there and then move it to a staging area to be racked later.

11. How To Unload Your Shipping Container of RTA Cabinets When You Have a Dock

Your container will be floor loaded, which means the cartons are not on pallets. They are stacked directly on the floor of the container. Therefore, each box will have to be removed by hand.

Begin unloading by removing boxes and placing them on pallets placed on the floor in front of the open container.

After you have removed enough cartons to create space inside the container, you can build a pallet inside the container and remove it using a pallet jack or forklift.

An expandable gravity conveyor system makes it much easier to bring cartons from the back of a 4 ft container. You can rent one. Same with forklifts and pallet jacks in you’re not ready to commit to purchasing.

With the conveyor, you only 1 or 2 guys in the container and 1 or 2 to take cartons off and load on a pallet.

12. How Much Warehouse Space is Needed to Accommodate a Shipping Container of RTA Kitchen Cabinets?

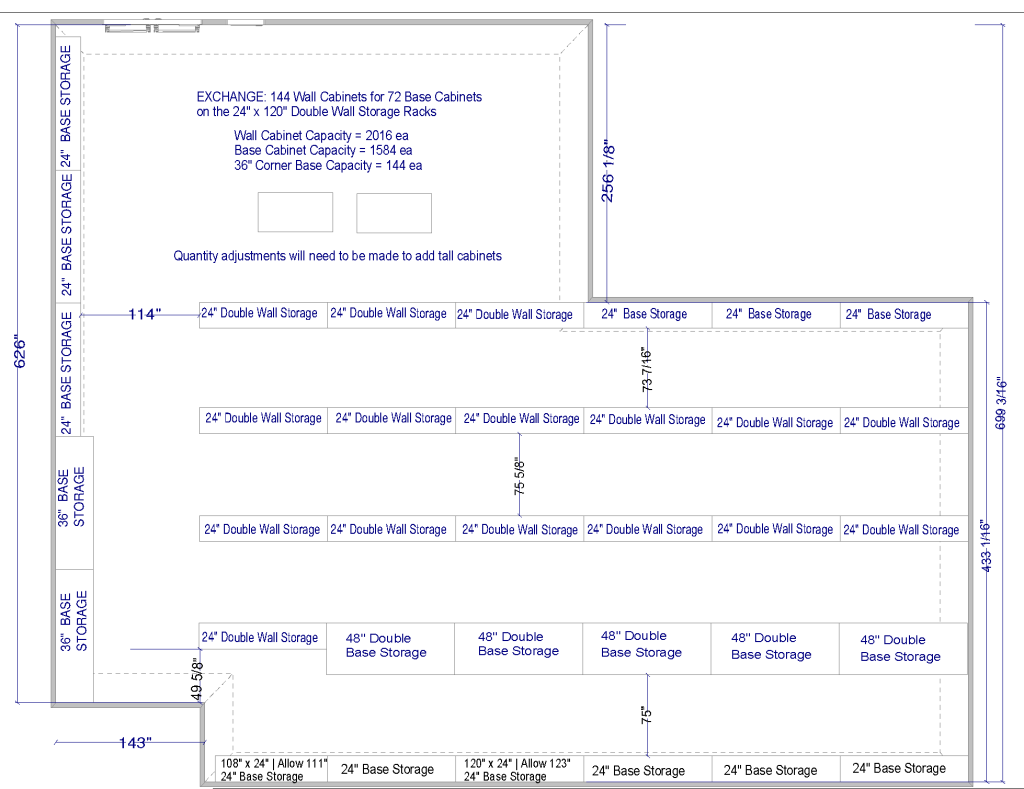

With the right racking and reasonable ceiling height and space between the aisles, you can store three containers of RTA cabinets in 4,500 – 5,000 square feet.

Two shipping containers of RTA cabinets can fit in 3,000 – 3,500 square feet, but it is tight.

Ten feet minimum ceiling height is required.

The photos below shod the racking layout of actual RTA kitchen cabinets in a warehouse after the container has been unloaded.

Also, you’ll need to leave space for an assembly and staging area since you are probably assembling RTA cabinets.

There are a number of factors that can’t be accounted for, like multiple wall cabinet heights or colors that demand more space to organize efficiently,

We can discuss this specifically when you place an order.

13. What Else Do You Need to Know About How to Buy RTA Kitchen Cabinets in Bulk?

Best advice for a successful first time buying a container load of RTA kitchen cabinets is to plan ahead. Use this list to assist with your planning.

- How many containers should you buy?

- Have your finances in place

- Decide whether to hire a broker or do it yourself

- Assemble your inventory list

- Figure out your racking layout

- Schedule your container delivery appointment

- Have equipment in place

- Hire 4 – 5 workers for 2 – 3 hours. Tell them to wear proper footwear.